In the realm of purchasing pepper and salt mills, the significance of scrutinizing and evaluating suppliers and products cannot be overstated. The stringent requirements for quality and safety, given their close contact with food, make it imperative to choose reliable suppliers.

The significance of scrutinizing and evaluating suppliers and products in the realm of purchasing pepper and salt mills cannot be overstated. The stringent requirements for quality and safety, given their close contact with food, make it imperative to choose reliable suppliers.

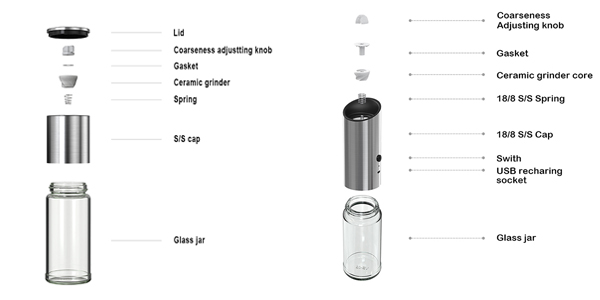

However, before learning about pepper grinder factories, it's important to first understand the basic structure of pepper grinders. Overall, pepper grinders can be divided into two main categories - manual grinders and electric grinders. As the name suggests, manual grinders require twisting, pressing, or other physical effort to grind. Electric pepper grinders are mainly activated by buttons or gravity mechanisms.

(Manual grinder structure) (Electric grinder structure)

(Manual grinder structure) (Electric grinder structure)

From the diagrams above, we can see that manual and electric grinders have basically the same structure. The main factors to focus on are the grinder's materials (plastic, stainless steel, glass, wood) and the material of the grinding burr - this is very important. Grinding burrs generally come in ceramic or stainless steel.

- Ceramic Burr:

Famous for its high wear resistance and hardness, ceramic is second only to diamond in hardness and sharper than stainless steel. Ceramic burrs do not produce pores, making them highly resistant to bacterial growth. Ceramics have low thermal conductivity, which helps maintain aromatic oils. They are corrosion-resistant, durable, and eco-friendly. Ceramic grinding mechanisms work for various spices, including salt and pepper, although their efficiency may not be as high as stainless steel.

- Stainless Steel Burr:

Stainless steel burrs offer high hardness, durability, and wear resistance. However, due to potential corrosion, they are not ideal for coarse salt. Poor quality stainless steel may have low purity and be prone to rusting.

Now that we've covered the basics of pepper and salt grinder structures and factors, if you want an even more in-depth understanding, you can read this blog post: Comprehensive Guide to Choosing the Perfect Salt and Pepper Grinder

Next, let's explore the key considerations when selecting the ideal pepper grinder factory:

Environmental Survey and Quality Management:

Conducting an environmental survey is a crucial initial step. Ideally, a physical inspection of the factory provides firsthand insight into its strength and corporate culture. In cases where on-site visits are impractical, reviewing authentic images on the factory's website or utilizing VR factory inspections can help assess its capabilities.

Additionally, Food-grade materials and finishes are crucial for kitchenware. Ensure polymers, metals, and paints are non-toxic. Reputable factories comply with ISO, LFGB, BRC, FDA standards.

Product Innovation and R&D Strength:

Apart from production strength, evaluating the factory's research and development capabilities is essential. A factory with robust R&D can independently innovate and customize products. Examining existing products and the R&D team's capacity to introduce new designs or improvements is vital. Factories recognized with design awards, such as the red dot award, signal innovation and trendsetting capabilities.

Customer Evaluations and Collaborations:

Investigate customer reviews and the factory's existing clientele to gauge its excellence. Positive feedback and collaborations with reputable brands attest to the factory's reliability and strength. A factory with a history of satisfied customers is likely to offer secure communication and reliable after-sales services.

Email Communication and Staff Quality:

Engage in email correspondence to inquire about offers, samples, and delivery times. This serves a dual purpose: assessing the factory's responsiveness and determining the staff's professionalism. The quality of communication and the staff's knowledge reflect the overall corporate culture and strength of the factory.

By thoroughly vetting pepper grinder factories across these factors, you can identify the ideal partner that ticks all the boxes - food safe, innovative, reliable, and responsive. Use these tips to make a confident manufacturing selection.

Unsure where to begin your pepper mill manufacturing search? Look no further than Chinagama -your reliable salt and pepper mills factory partner.

●Professional 12-Engineers Team with profound experience of OEM, help you to create item from design or drawing.

●10-designers team with excellent design ability, 2018 Red dot Award, 2019 3xiF Award, 2021 IF Award, more than 300 patents.

●Strict Quality Assurance Planning includes aging test, life cycle test, material test, to assure products qualified.

●Food-contact safety raw material, comply with LFGB/FDA.

●Long-term cooperation relationship with many famous kitchenware brands over the world, key supplier to OXO, Goodcook, Chef'n, CuisiproGEFU, EVA SOLO, Stelton, Tchibo, MUJI, Lock & Lock.

●ISO9001, BSCI, BRC CP/FOOD audit, LFGB/FDA cert…, updated annually.

●non-dust filling workshop, can help you fill and labeling salt and peppercorn certificated.

●152 workers, 78 staffs, 36njection machines, 12 assembling lines to assure you a quick delivery time.

Post time: Nov-16-2023

Home

Home